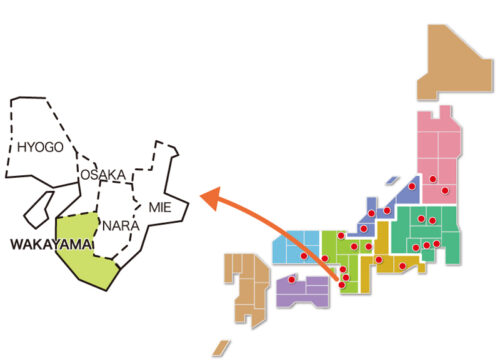

Wakayama Region

Japan’s largest producer of circular knitted fabrics

When it comes to the production of circular knit textiles, Wakayama leads the way nationwide. The main benefits of such fabrics include exceptional stretchability with a soft texture, plus a production process allowing shorter delivery lead times than woven textiles. Knit materials accommodated range from cotton, wool, silk and linen right up to polyester, rayon and tencel.

The catalyst came back in 1909, when five circular knitting machines were introduced from Switzerland and business soared during the Taisho Period (1912-1926), when cotton knits were developed by leveraging a raising and brushing technique on Kishu (Wakayama) flannel. Next, in the Showa Period (1926-1989), came circular interlock knitting machines followed by the advent of synthetic knitwear known as jerseys post-war for a wider scope of end uses, ranging from underwear to ladies’ wear and sportswear across the board. Despite these successes, however, growing imports of low-priced products put the industry under severe pressure. Currently, the Wakayama textile region strives to enhance product development alongside planning/proposition capability while focusing on better service to deal with multi-ranged products in small batches and short delivery.